To say that the materials science industry is going through a massive boom right now is no exaggeration. From self-growing hydrogels to artificial skin grown from spider silk, it seems the possibilities for materials are limitless.

Now, scientists Lina González and Christopher Voigt from the Synthetic Biology Center at MIT have developed a living material that can survive long periods and in extreme conditions. In short, it is the most resilient living material created by humans yet.

Living materials can be found everywhere in nature, some of the best-known examples include your skin, bone and wood. More specifically, these are all materials in which cells are embedded within a structural scaffold, allowing them to carry out useful functions such as sensing the environment, carrying out repairs and harvesting energy – almost in symbiotic fashion.

What makes these living materials so alluring is that they can survive for a long time – some for millennia – adapting under constantly changing and stressful conditions. It is no wonder that there is significant interest in artificially engineering responsive bio-inspired materials.

Making a living material: a brief history

Previous methods to achieve this involved 3D printing bacterial cells, allowing them to be organised onto a scaffold at sub-millimetre resolution. These cells could be introduced on the surface of a biofilm scaffold or spread over a soft and flexible material such as a hydrogel. The problem with this approach, however, was that bacteria were still unable to be printed within the scaffold material itself – thus not being a true “living material”.

This was until “bio-inks” were developed, a material that can incorporate and hold living cells together. This had massive implications for 3D printing, allowing for the construction of intricate tissue models.

Xuanhe Zhao and his colleagues at MIT recently developed a bio-ink based on the bacterium E. coli, showing that the bacterial cells were still able to perform sensing and computing functions whilst incorporated within a scaffold. But there was one problem: the E. coli-based living material only remained functional for a few days after printing.

Chao Zhong and his team from Shanghai Tech University in China went a step further creating a living material based on the bacterium B. subtilis that were able to survive at 4 degrees Celsius for five weeks.

Introducing spores: the game-changers

González and Voigt realised that rather than embedding bacterial cells within structural scaffold materials, as the previous researchers had done, they could instead embed bacterial spores.

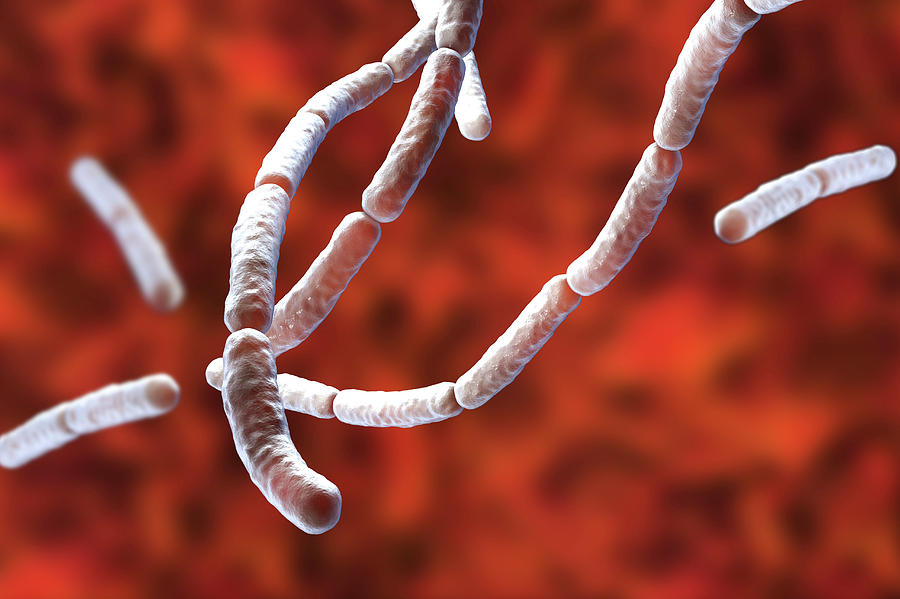

When bacteria face adverse conditions, they morph into small, yet tough structures called endospores that can lie dormant – some for millions of years. It’s a last ditch, extreme survival strategy; allowing bacteria to survive high temperatures, high pressures, X-rays, gamma-radiation, UV-light, and go long periods without water and nutrients. When the environment becomes more favourable (for example, upon hydration), the endospore can reactivate itself.

Armed with this knowledge, González and Voigt modified a 3D printer to print B. subtilis spores and embed them into a hydrogel scaffold.

The results were promising. Not only were the endospores able to reactivate and perform their programmed function after significant radiation exposure and dehydration, they were also able to survive at temperatures of 100 degrees Celsius.

KATERYNA KON/SCIENCE PHOTO LIBRARY

Furthermore, the spores were found to 3D print more evenly across the hydrogel compared to printing bacterial cells, thus making a more robust living material that can more efficiently self-heal.

Perhaps most importantly, the 3D printed spores were able to survive for a month (the maximum tested) and reactivate when rehydrated, without any loss of function. González and Voigt expect that, given the known longevity spores are capable of, they can potentially be stored indefinitely.

The bigger picture

Although living materials already have promising biomedical applications (such as growing artificial tissues or even simulating a medical laboratory on a chip), the potential is far greater.

Cells could be harnessed for their sensing, self-cleaning and self-healing capabilities – an application that could revolutionise modern architecture. Microbes have already been harnessed in the manufacture of bio-hybrid textiles to control material breathability in response to sweat. Some engineered bacteria have even been shown to build metal wires within electronics.

Spore-containing living materials will be a game-changer in responsive materials that are needed to function in an open environment – such as pollution remediation. Perhaps, spore-containing living materials and their ability to survive extreme environments could even hold the key to terraforming other planets. I hope you’re listening, Elon Musk!

Journal reference: bioRxiv, DOI: 10.1101/537571.